Zaɓin zaɓi na rini da karewa ya dogara ne akan nau'ikan iri-iri, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun buƙatun samfuran masana'anta, wanda za'a iya raba shi zuwa pre-jiyya,rinig, bugu, bayan kammalawa da sauransu.

Kafin magani

Filayen dabi'a sun ƙunshi ƙazanta, a cikin tsarin sarrafa kayan yadi kuma suna ƙara slurry, man fetur da gurɓataccen datti, kasancewar waɗannan ƙazanta, ba wai kawai hana ci gaba mai kyau na rini da kammala aiki ba, amma har ma yana shafar aikin lalacewa na masana'anta.

Manufar riga-kafi ita ce yin amfani da sinadarai da aikin injiniya na jiki don cire ƙazanta a kan masana'anta, sanya masana'anta su zama fari, mai laushi, kuma suna da kyakkyawar dacewa don saduwa da bukatun shan, da kuma samar da samfurori masu dacewa don rini, bugu da ƙarewa.

Auduga: shirye-shiryen danyen tufa, waƙa, desizing, tafasa, bleaching, mercerizing. Polyester: shirye-shiryen zane, mai ladabi (ruwa alkali, da dai sauransu), preshrinking, ajiyar wuri, alkali deweighting (ruwa Alkali, da dai sauransu).

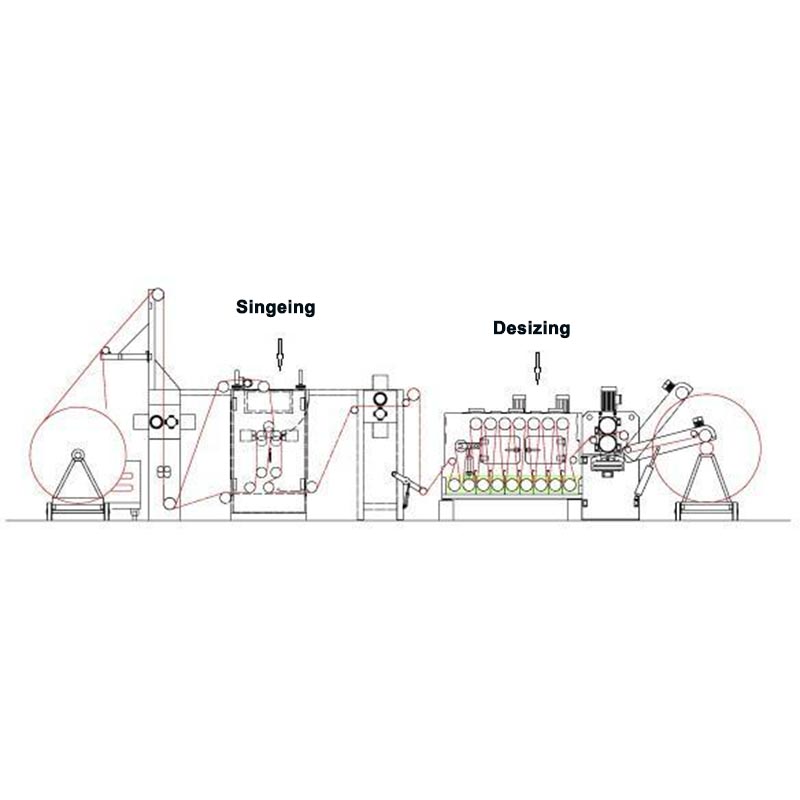

Yin waƙa

Yawanci, bayan shigar da masana'antar bugu da rini daga masana'anta, yakamata a fara bincika tufafin launin toka, a juye, yin baƙar fata, bugu da ɗinki, sannan a rera waƙa.

Dalilai:

(1) a kan tufa ba sa raira waƙa da yawa, tsayi daban-daban;

(2) matakin gamawa mara kyau, gurɓataccen gurɓataccen abu;

(3) a cikin jeri zhongyi ulu rini da karewa, bugu da rini.

Manufar rera waƙa:

(1) inganta kyalle; Inganta gamawa;

(2) inganta juriya na pilling (musamman masana'anta fiber na sinadarai);

(3) inganta salon, rera waƙa na iya sa masana'anta ta zama kintsattse, sun kasance kashi.

Dessing

A cikin aikin saƙar, warp yana fuskantar babban tashin hankali da rikici, wanda ke da sauƙin karya. Don rage raguwar warp, inganta aikin saƙa da ingancin masana'anta mai launin toka, wajibi ne a daidaita girman yarn kafin saƙa. Fiber a cikin zaren yana mannewa kuma yana riƙe tare, kuma yana samar da fim mai ƙarfi a saman zaren, yana sa zaren ya zama mai ƙarfi da santsi, don haka inganta ƙarfin karyewa da juriya na zaren.

Ƙimar manufa: Bayan girman, slurry yana shiga cikin zaruruwa kuma wani ɓangare yana manne da saman warp. Yayin da yake inganta aikin zaren, slurry yana gurɓata rini da kammala sarrafa ruwa, yana hana mu'amalar sinadarai tsakanin zaruruwa da rini da kayan sinadarai, kuma yana da wahala a aiwatar da rini da kammala aikin.

(1) Gabatarwa ga slurry da aka saba amfani da su

Na halitta slurry: sitaci, seaweed danko, danko, da dai sauransu.

Kayayyakin sitaci:

① a cikin yanayin lalata acid;

② a cikin yanayin kwanciyar hankali na alkali, kumburi;

③ a cikin yanayin oxidants za a iya bazuwa;

④ ta sitaci bazuwar enzyme bazuwar.

Chemical slurry: cellulose samu irin su hydroxymethylcellulose (CMC), polyvinyl barasa (PVA), polyacrylic acid, polyester, da dai sauransu.

PVA Properties:

① barga zuwa acid da tushe, danko baya ragewa;

② Ana lalata shi da oxidant.;

③ Wide applicability, mai kyau dacewa, babu hadawa dauki

(2) Hanyoyin ɓata lokaci da aka saba amfani da su

1. Alkaline desizing

Ɗaya daga cikin hanyoyin da aka fi amfani da su a cikin tsire-tsire masu rini na gida, amma raguwar raguwa ba ta da yawa, kuma ana iya cire wasu ƙazanta yayin da ake desizing.

Mechanism: Yin amfani da maganin sodium hydroxide dilute solution, sitaci slurry a ƙarƙashin aikin kumburin alkali (ko kumburi) al'amari, ba ya faruwa da sinadarai, ta yadda slurry daga gel zuwa sol, rage daurin dauri tsakanin fiber da slurry, sa'an nan kuma amfani da wankewa da inji karfi don cire shi. Don PVA da polyacrylate slurries, yana iya narkar da sodium hydroxide a cikin mafita mai narkewa.

(sitaci) enzyme desizing

Enzymes kuma ana kiran su enzymes, biocatalysts.

Siffofin: babban ɓata lokaci, ba fiber na rauni ba, kawai don sitaci, ba zai iya cire ƙazanta ba.

Siffofin: a. Babban inganci. b. Ƙayyadaddun abu: Enzyme na iya haifar da amsa ɗaya kawai ko ma takamaiman amsa. c. Yanayin zafin jiki da ƙimar PH ya shafi aikin.

Don sitaci slurries ko sitaci gauraye slurries (abun sitaci ne rinjaye), amylase za a iya amfani da desizing.

Desizing acid

Aikace-aikacen gida ba shi da yawa, saboda amfani yana da sauƙi don lalata fiber, ƙari tare da sauran hanyoyin. Ana ɗaukar hanyar matakai biyu: alkali desizing - desizing acid. Desizing acid zai iya yin sitaci hydrolyzes, cire ma'adinai gishiri da sauransu, da kuma gyara ga juna.

Oxidation desizing

Oxidizing wakili: NaBrO2 (sodium bromite) H2O2, Na2S2O8, (NH4) 2S2O8, da dai sauransu.

Ka'ida: Ma'adinin oxidizing zai iya oxidize da lalata kowane nau'in slurry, nauyin kwayoyinsa da danko yana raguwa sosai, ana ƙara yawan ruwa, kuma ana hana slurry daga manne da fiber, sa'an nan kuma an cire hydrolyzate ta hanyar wankewa mai kyau.

(1) tafasa

Manufar tafasa shi ne don cire ƙazantattun fiber da inganta kayan aiki na masana'anta, musamman ma datti.

Najasa na dabi'a: Don yadudduka na auduga mai tsabta, galibi fiber co-organisms ko halittu masu alaƙa, gami da kakin mai, pectin, furotin, ash, pigment da harsashi na auduga.

Najasa na wucin gadi: ƙazanta irin su mai, wakili na antistatic da mai, tsatsa da sauran slurry da aka ƙara a cikin juzu'i da sarrafa saƙa.

Wadannan ƙazanta suna da tasiri sosai akan wettability na masana'anta kuma suna hana rini da ƙare masana'anta, kuma dole ne a cire su a cikin tsarin scouring tare da sodium hydroxide a matsayin babba da surfactants azaman taimako.

(2) Bleaching

Bayan tafasa, mafi yawan na halitta da kuma wucin gadi ƙazanta a kanmasana'antaana cirewa, amma don yadudduka masu bleached da haske, ana kuma buƙatar bleaching. Wato cire pigment, inganta fari a matsayin babban dalilin sarrafa bleaching.

Sinadarin fiber ba ya ƙunshi pigment, bayan tafasa ya kasance fari sosai, kuma fiber na auduga bayan scouring pigment har yanzu akwai, da fari ba shi da kyau, don haka bleaching yafi na halitta datti a kan auduga fiber.

(3) Bleach

Nau'in Oxidation: sodium hypochlorite, hydrogen peroxide da sodium chlorite, da dai sauransu, galibi ana amfani da su a cikin fiber na auduga da yadudduka masu gauraya.

Rage: NaHSO3 da inshora foda, da dai sauransu, galibi ana amfani da su don yadudduka na fiber na furotin.

(4) Sodium hypochlorite bleaching:

Sodium hypochlorite bleaching yawanci ana amfani da shi don bleaching auduga yadudduka da auduga blended yadudduka, da kuma wani lokacin kuma amfani da bleaching polyester auduga blended yadudduka. Duk da haka, ba za a iya amfani da shi don bleaching sunadaran zaruruwa kamar siliki da ulu, saboda sodium hypochlorite yana da lalata tasiri a kan furotin fibers, da kuma sa zaruruwa yellowing da lalacewa. A cikin tsarin bleaching, ban da lalata al'amuran halitta, ƙwayar auduga da kanta na iya lalacewa, sabili da haka, ya zama dole don sarrafa yanayin tsarin bleaching, don haka ingancin bayyanar da ingancin ciki ya cancanci.

Sodium hypochlorite yana da sauƙin ƙira, ƙananan farashi, aikin aikin bleaching na sodium hypochlorite yana dacewa, kayan aiki mai sauƙi, amma saboda sodium hypochlorite bleaching yana da kyau ga kare muhalli, don haka a hankali ya maye gurbin shi da hydrogen peroxide.

(5) Hydrogen peroxide bleaching H2O2:

Hydrogen peroxide, wanda kuma aka sani da hydrogen peroxide, yana da tsarin kwayoyin H2O2. Ana kiran bleaching hydrogen peroxide bleaching oxygen. A zaman lafiyar hydrogen peroxide bayani ne sosai matalauta a karkashin alkaline yanayi. A sakamakon haka, hydrogen peroxide na kasuwanci yana da rauni acidic.

Fabric bleached tare da hydrogen peroxide yana da kyaun fari, tsaftataccen launi, kuma ba shi da sauƙin yin rawaya lokacin adanawa. Ana amfani da shi sosai wajen bleaching masana'anta auduga. Oxygen bleaching yana da mafi girma karbuwa fiye da chlorine bleaching, amma hydrogen peroxide ya fi sodium hypochlorite farashin, kuma oxygen bleaching na bukatar bakin karfe kayan aiki, makamashi amfani ne ya fi girma, farashin ya fi chlorine bleaching.

A halin yanzu, ana amfani da hanyar buɗaɗɗen buɗaɗɗen tururi a cikin masana'antar bugu da rini. Wannan hanya tana da babban mataki na ci gaba, aiki da kai da kuma samar da ingantaccen aiki, saurin tsari mai sauƙi kuma baya haifar da gurɓataccen muhalli.

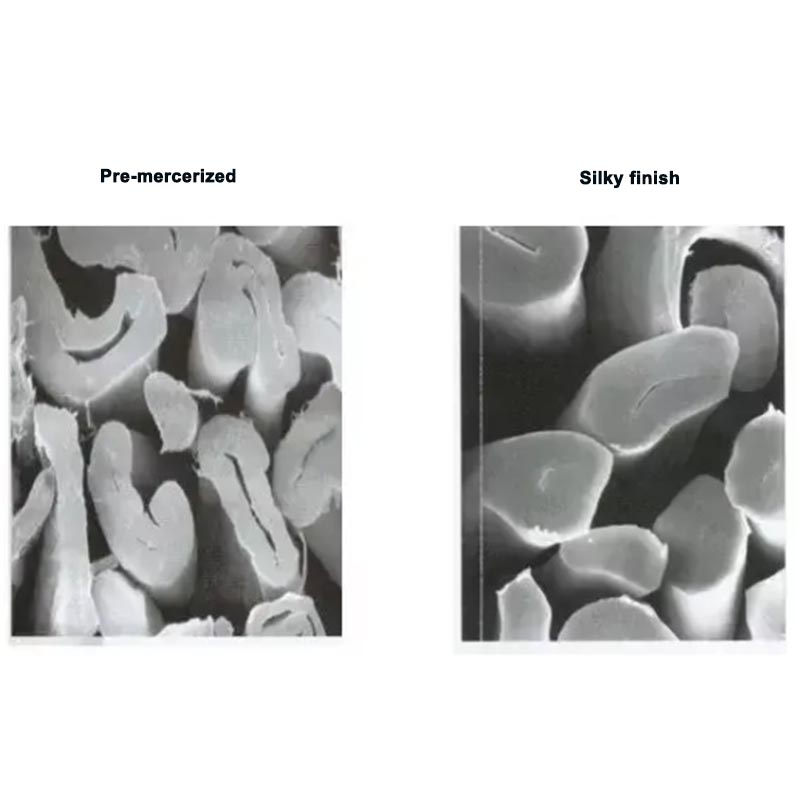

5. Mercerized (auduga masana'anta)

Textiles karkashin wani yanayi na tashin hankali, tare da taimakon mayar da hankali caustic soda, da kuma kula da girman da ake bukata, na iya samun siliki luster, wannan tsari ake kira Mercerization.

(1) Manufa ta hayar:

A. Inganta ƙwanƙwasa mai haske da jin daɗin masana'anta, saboda kumburin fiber, tsarin fiber ɗin ya fi dacewa, kuma hasken haske ya fi na yau da kullun, don haka inganta sheki.

B.Increase da kudi na rini launi bayan mercerizing gama, fiber zone ragewa, amorphous yankin karuwa, da kuma dyes ne mafi kusantar shigar da zaruruwa, canza launi fiye da mercerized auduga fiber ya karu da 20%, da haske inganta, a lokaci guda ƙara matattu gaban rufe ikon.

C.Don inganta girman kwanciyar hankali mercerizing sun kammala aikin ƙira, na iya kawar da wrinkles na igiya, ƙarin na iya biyan buƙatun ingancin rini da buga samfuran rabin-da-rabi. Abu mafi mahimmanci shi ne cewa bayan mercerizing, kwanciyar hankali na nakasar fadada masana'anta ya inganta sosai, don haka yana rage yawan raguwar masana'anta.

6. Refining, pre-shrinking (sunadarai fiber masana'anta)

Makasudin tace mai kafin ya rage shi ne don cire mai, slurry da datti da ake yadawa akan masana'anta (fiber) a lokacin ajiyar saƙa da sufuri, kuma a lokaci guda, wasu oligomers akan fiber ɗin kuma ana iya narkar da su a cikin tacewa mai zafi. Tufafin launin toka ya kamata a riga an datse kafin adadin alkali, sannan a saka abubuwan da ake hadawa kamar su olein da caustic soda. Pretreatment na sinadaran fiber masana'anta da za'ayi a high zafin jiki da kuma high matsa lamba rini inji.

7.Alkali rage (chemical fiber masana'anta)

(1) Ka'ida da tasirin rage alkali

Maganin rage alkali shine tsarin kula da masana'anta na polyester a cikin zafin jiki mai zafi da mai daɗaɗɗa mai ƙonewa. Polyester fiber ne hydrolyzed da karya ta ester bond na polyester kwayoyin sarkar a saman fiber a cikin sodium hydroxide ruwa bayani, da kuma hydrolysis kayayyakin da daban-daban polymerization digiri suna ci gaba da kafa, kuma a karshe ruwa-soluble sodium terephthalate da ethylene glycol aka kafa. Kayan aikin rage alkali sun hada da injin rini mai ambaliya, injin rage ci gaba, injin rage lokaci-lokaci iri uku, sai na'urar rini mai ambaliya; Na'urori masu ragewa na ci gaba da na ɗan lokaci na iya sake yin amfani da ragowar lemun tsami. Don tabbatar da kwanciyar hankali na siffar bayyanar da girman launin toka mai launin toka don wasu samfurori na rage alkali, wajibi ne don ƙara tsarin da aka riga aka ƙaddara, sannan shigar da tsarin rini.

Lokacin aikawa: Fabrairu-28-2025